CNC Turning

CNC Turning

A PASSION FOR CNC TURNED PARTS

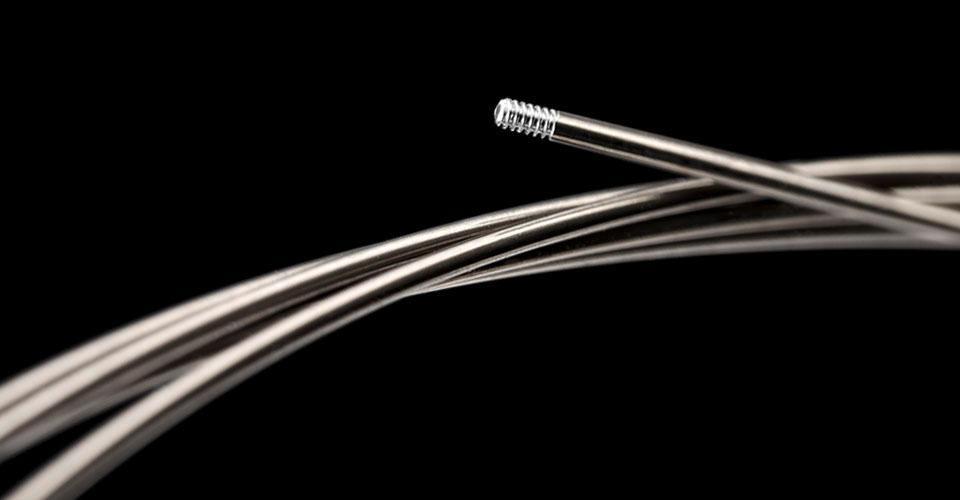

We are devoted to turning parts: KSP produces precision turned parts for the highest requirements used in many areas of application. In our production we use modern CNC controlled lathes and machining centres to turn parts from bars up to a diameter of Ø 42 mm and Ø 70 mm in the chuck.

CORE EXPERTISE

- Materials difficult to machine (titanium, stainless steel, special materials)

- Small parts from approx. Ø 0,61 mm up to Ø 42 mm from the bar, Ø 70 mm in the chuck

- Complex geometries with low tolerances

- Precision in the micrometre range (from 0.001 mm)

- Surface finishing (coating, polishing, sandblasting, etc.)

- Service: 3D printing, CAD, cleanroom, laser marking, logistics

TITANIUM TURNED PARTS

We produce the majority of our CNC turned and milled parts for medical engineering applications. The biocompatibility of titanium and its resistance to acids make the metal the material of choice. Every year we process between 20,000 and 30,000 meters of titanium and titanium alloys to produce highly precise components.

STAINLESS STEEL TURNED PARTS

It's all about the alloy. This means there can be big differences in the machining of stainless steel alloys. We know about these differences and use the right machining processes in order to achieve the specific characteristics of the stainless steel required for your components.

TURNED PARTS FROM OTHER MATERIALS

For us materials are living and formable. We also turn parts from aluminium, plastic, molybdenum, nitinol or nickel-iron alloys. Our team is experienced and has the necessary know-how to individually address the specialities of the respective material and get the best results.

TURNING WITH OR WITHOUT A SLIDING HEADSTOCK

KSP is your contact partner for the turning of highly precise parts with or without a sliding headstock from materials which are difficult to machine. Our range of machines includes modern lathes with or without a sliding headstock from Star, Emco and Doosan.

PRECISION TURNED PARTS

KSP stands for precision in the micrometre range (from 0.001 mm) and for components with an immaculate appearance. Many of our customers process our turned parts under the microscope and for this purpose an immaculate surface is a must. In order to realise this we attach great importance to parts with a surface finish and during the production process use microscopes on each machine to check the quality.

Depending on the customer requirements, we can offer surface treatment and surface modifications of the base material, for example, with polishing, glass bead blasting, anodisation and also functional coatings and ensure smooth operation of all internal and external process steps.

KSP delivers certified quality with high quality materials. These conform to the EU directive 2011/65/EU (RoHS 2) and EU directive no. 907/2006 (REACH).

MATERIALS DIFFICULT TO MACHINE

KSP works with materials and rust-free alloys which are difficult to machine. Many lathe shops or CNC machining companies prefer not to work with such materials because they require a high degree of specialisation and expertise. These metals include titanium, titanium alloys and stainless steel. Titanium requires certain protective equipment and therefore the machine setup has to take this into account, for example, through special coolants and safety devices.

The maintaining of stocks of especially titanium and stainless steel in certain dimensions enables short reaction times. The production is made in batches so that after the manufacturing process is finished we are able to trace the origin of the precision components.

WE MACHINE AND PROCESS:

- Titanium and titanium alloys: grade 2, grade 4, grade 5

- All rust-free steel alloys such as: 1.4301, 1.4305, 1.4307, 1.4404, 1.4112, etc.

- Aluminium alloys, e.g.: AlMgSi1, AlMg3, AlMg4,5Mn, AlZnMgCu1,5

- Plastics including: PEEK, POM, PPS, PPSU, PSU, PVDF and PTFE (Teflon), tecanat and tecapeek

- Special materials: nitinol, molybdenum, cobalt chrome molybdenum, nickel-iron alloys, etc.