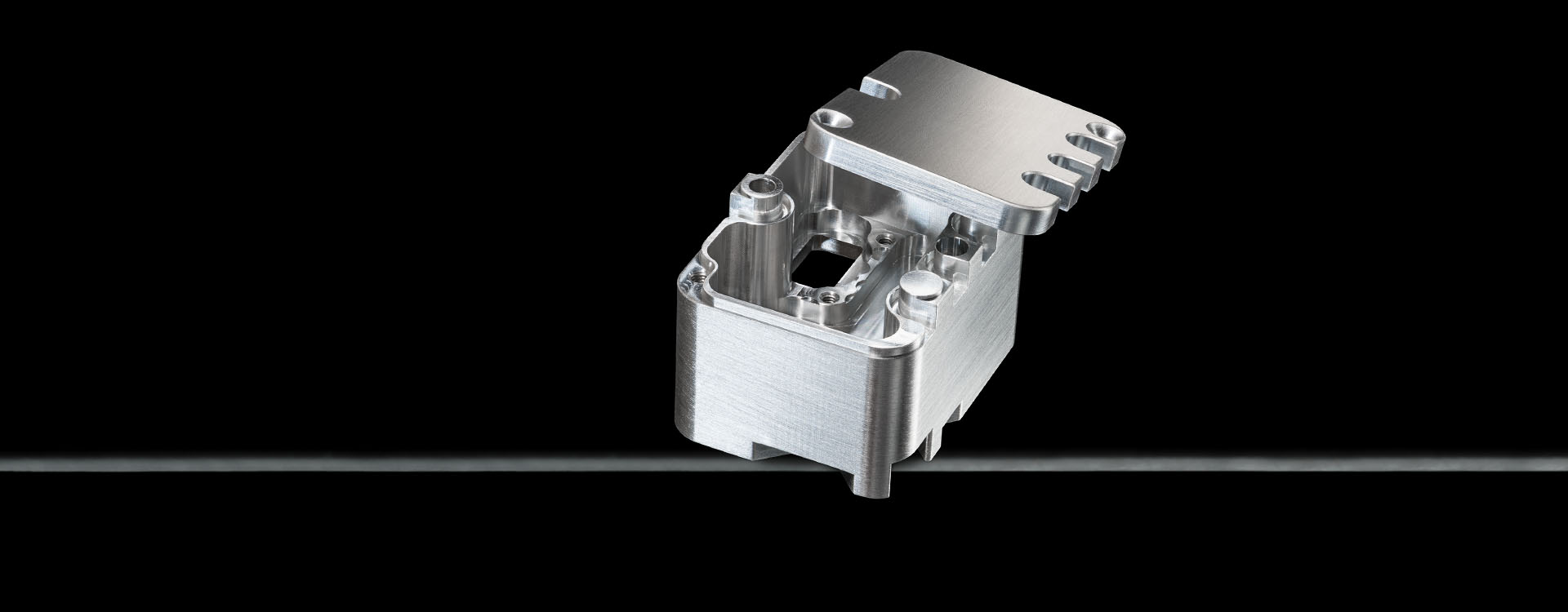

CNC Milling

HIGH QUALITY COMPONENTS FROM HIGH QUALITY MATERIALS

We produce each component with the utmost care, regardless of whether it is turned or milled in aluminium or plastic, is complex or simple in order to meet the special requirements of the respective material.

PRODUCT EXAMPLES

We produce, for example, high precision spinal implants from high quality plastic for orthopaedic applications or complex housings, covers and basic bodies from aluminium for optoelectronics, sensor technology and aerospace. These are just a few selected examples of our work. Click on the arrows in the pictures to see the applications.

ALUMINIUM – LIGHT BUT STABLE

There are many application areas for aluminium. In spite of its low weight it is extremely durable. Due to its good conductivity and shielding properties aluminium is frequently used for housings for the purpose of shielding against electromagnetic radiation.

The protection offered by aluminium components against corrosion can be further enhanced through surface treatment such as anodising or passivation. We are happy to manage this production step for you to deliver the complete processed component which on request can be laser marked or fitted to an assembly.

We machine aluminium alloys including AlMgSi1, AlMg3, AlMg4.5Mn, AlZnMgCu1.5 and plastics such as POM, PPSU, Peek, Tecapeek and PTFE.

SPECIAL MATERIALS WITH SPECIAL REQUIREMENTS:

The machining of special alloys such as molybdenum, cobalt chrome molybdenum or nitinol is extremely demanding and requires a high level of technical expertise and years of experience. Our team is excellently equipped for such tasks and is familiar with special processes which are required in order to machine difficult and demanding materials.

We will be happy to find the best solution for your application.

We machine special materials including molybdenum, cobalt chrome molybdenum, nitinol, nickel-iron alloys, etc.