OUR BENCHMARK IS YOUR SATISFACTION

COMPLETE SOLUTIONS WITH FULL SERVICE

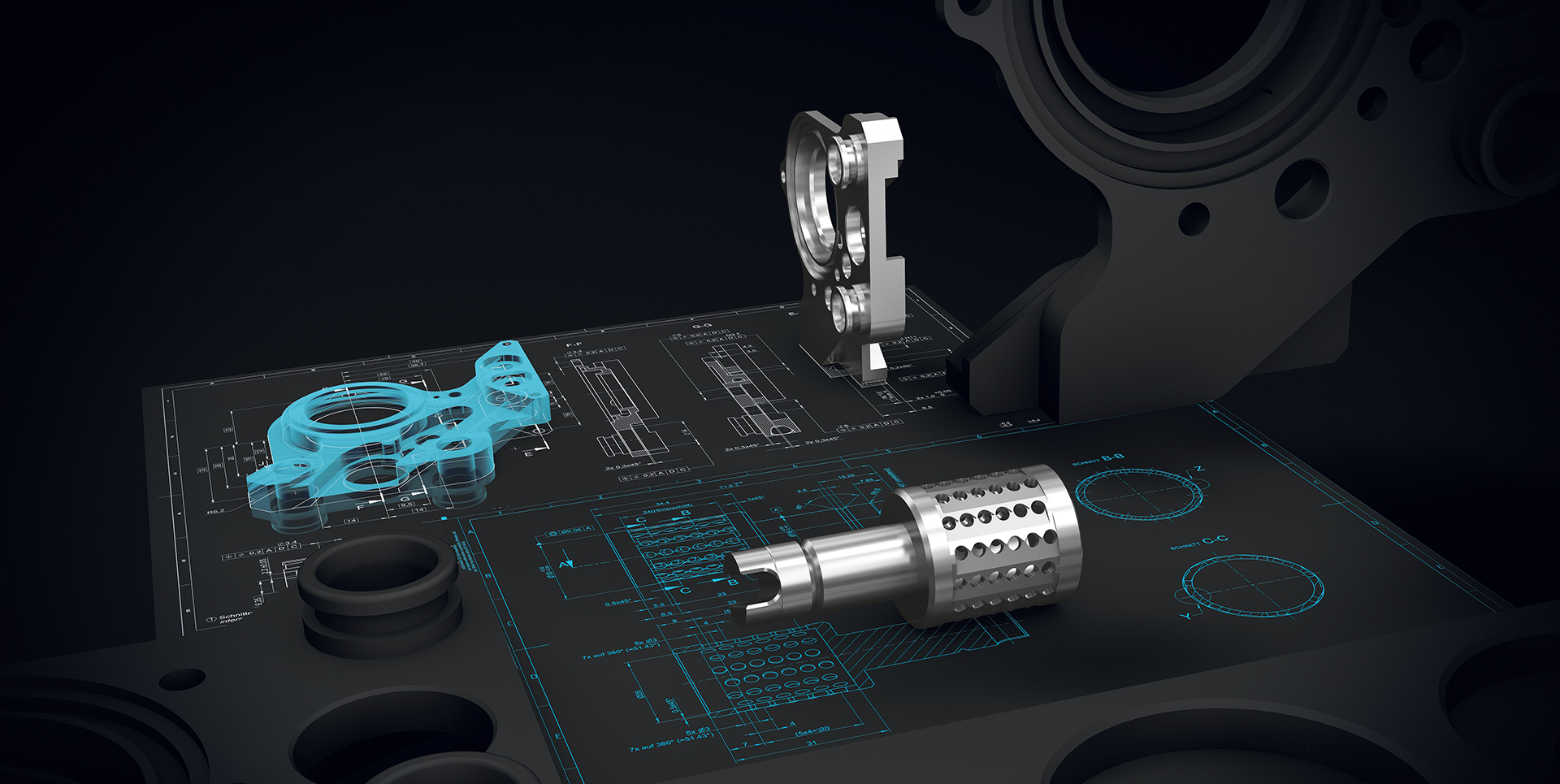

DESIGN | SERVICE | PRODUCTION

HIGHLY PRECISE CNC TURNED & MILLED PARTS

KSP produces small, precision CNC turned and milled parts with complex geometries for many varied applications. Our trademark is the processing of rust-free alloy materials which are difficult to machine. This includes titanium, titanium alloys, stainless steel and other special materials. Below you can see a selection of application areas and reference parts.

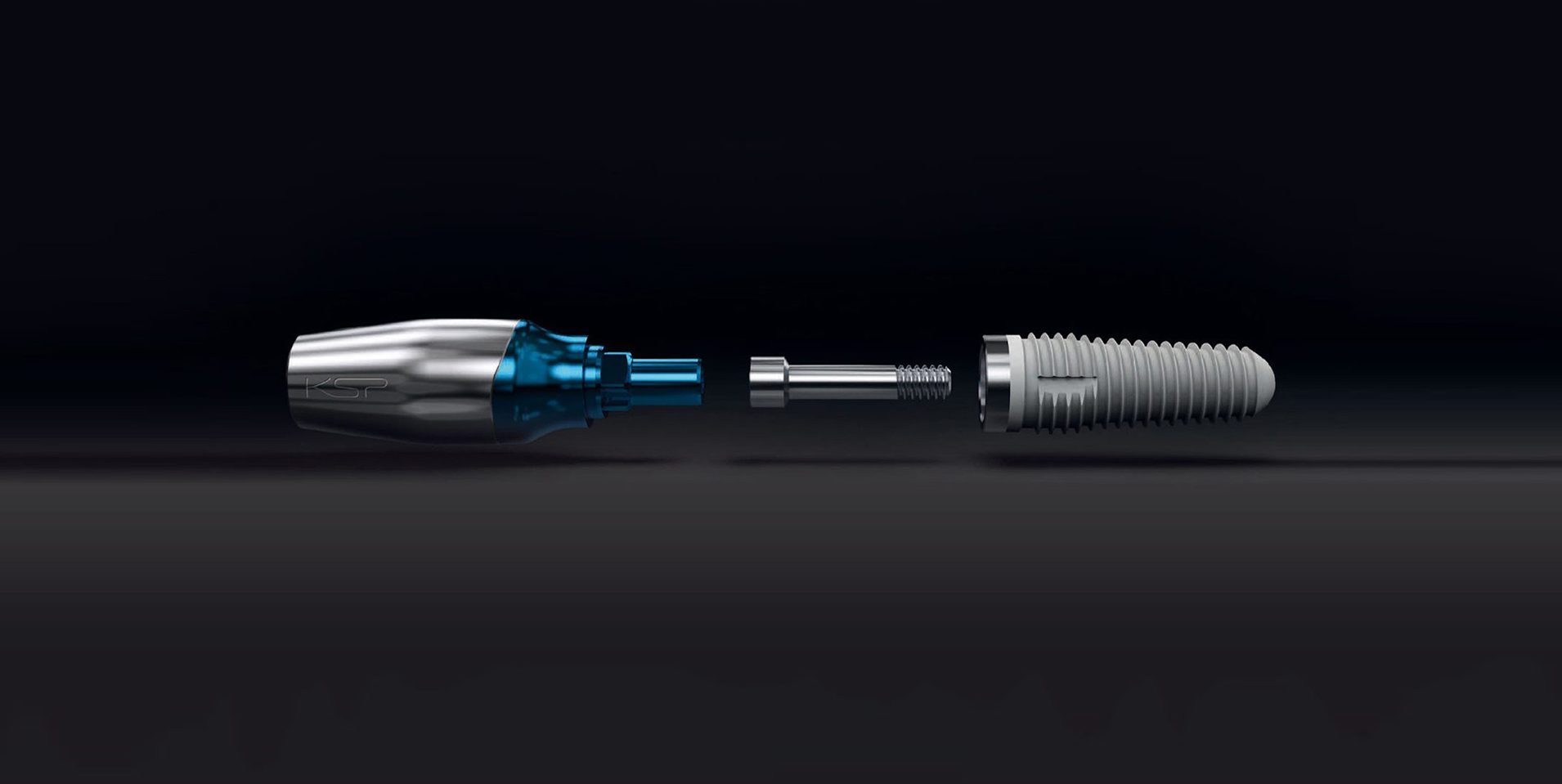

DENTAL TECHNOLOGY

The largest area of business at KSP is currently the field of turned and milled parts used in dental technology. When high requirements meet precision working the result is high quality. At KSP we use our modern range of machines to produce highly precise dental implants, dental abutments, transfer parts and screws and also all types of matching dental instruments.

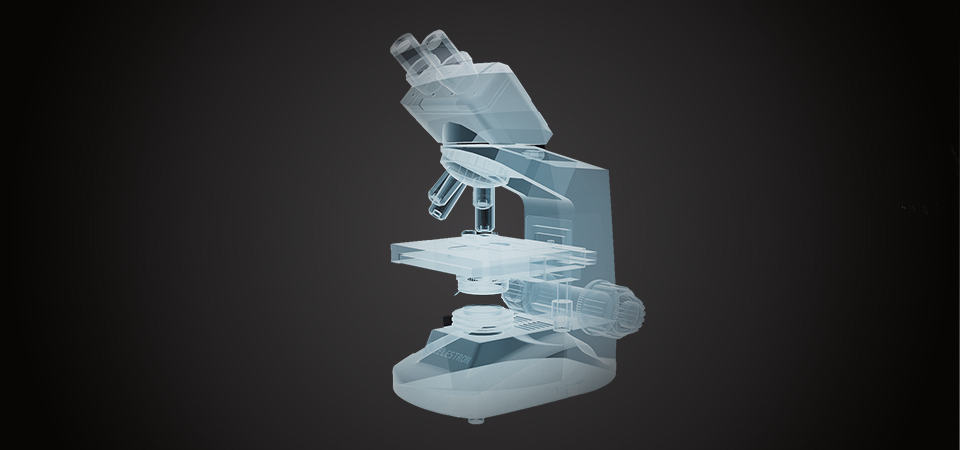

MEDICAL ENGINEERING

As well as components for dental products, in the field of medical engineering we also produce high quality components used in endoscopy applications and orthopaedics. This involves bone plates and screws, spinal implants and diverse medical engineering instruments. This is complemented by the cleanroom services we offer with sterile packing for components.

More

OPTOELECTRONICS / SENSORS

Complex contours in combination with low tolerances and demanding materials are common in the area of optoelectronics and sensor technology. Our skills and expertise are ideal to meet these requirements. We deliver turned and milled parts such as rings, joint components, housings and covers with an immaculate surface, often with a special finish.

AEROSPACE

Turned and milled parts for the field of aerospace have to meet the highest requirements. The production has to comply with the strictest standards. We are able to draw on our expertise from the field of medical engineering and apply it to aerospace applications. This enables us to deliver precision parts for many varied applications.

More

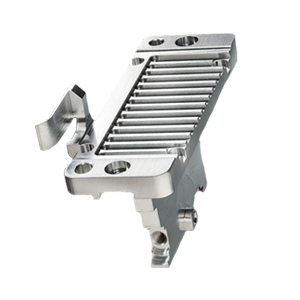

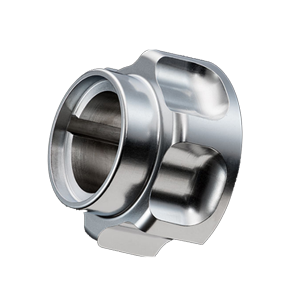

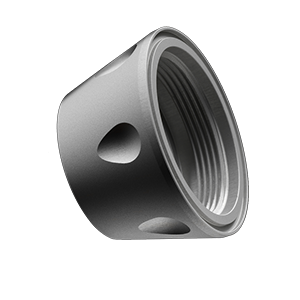

PRODUCT EXAMPLES

Dental implants

Bone plates

Aerospace components

Dental implants

Endoscopy components

Optoelectronics components

Dental instruments

Sensor technology components

Housings

Endoscopy components

Housings

Housings

TURNING SMALL PARTS IS OUR SPECIALITY

When it comes to milling and turning no customer part is too small for us. With our modern range of machines we produce CNC turned and milled parts with the lowest tolerances. We are able to produce small and medium-sized batches from 100 to 100,000 pieces.

News & Trade fairs, February 2022

MedtecLive with T4M

3.-5.5.2022 in Stuttgart

Nice that you were there. We look forward to meeting you again. Learn more

JOB OPPORTUNITIES AT KSP GmbH

We are looking for people with a feeling for precision because precision is necessary when we create products for our customers. In our company, highly qualified specialists work in the fields of machining, quality assurance, cleaning and logistics. Our team of experts with its extensive experience is able to make all the fine adjustments necessary to turn materials into precision components.

Learn more

HIGHEST QUALITY

KSP delivers high quality components. Our company is certified according to the following quality management standards: DIN EN ISO 13485, DIN EN ISO 14001, DIN EN ISO 9001. Our materials conform to the EU directive 2011/65/EU (RoHS 2) and EU regulation no. 1907/2006 (REACH).

YOU CAN RELY ON US

When we produce parts for you the real challenge is to maintain the very high internal standards we have for CNC turned and milled parts. Before your precision parts leave our production facility they are subject to a number of quality controls. The data produced by optical and 3D measurement devices is stored to enable future improvements. In addition, we have developed a sophisticated quality management system which we are continually refining. Finally, our service is complemented by customer-oriented order processing and efficient cooperation with our customers and suppliers. Please contact us if you wish to know more about our internal process steps.